INDUSTRIAL PAINTING

Our staff provides quality craftsmanship in the Industrial Market. Working in Steel plants, chemical plants, power plants, water plants, waste water plants and PetroChemical Plants. Our employees are apprenticeship trained through our local union apprenticeship program. And have their required OSHA training for on the job safety.

They have extensive training in class and on-the-job training in proper application of the following:

- Painting

- Abrasive Blasting

- Lead Abatement

- Pressure Washing 2,000 – 5000 psi

- Steam Cleaning 3,500 psi

- Tank coatings and linings

- Secondary Containment coatings

- Maintenance coating

- Parking lot striping

- Pipe and pipe rack coating

- High Performance Coatings

- Structural Steel coatings

- Industrial Signage

ENECON

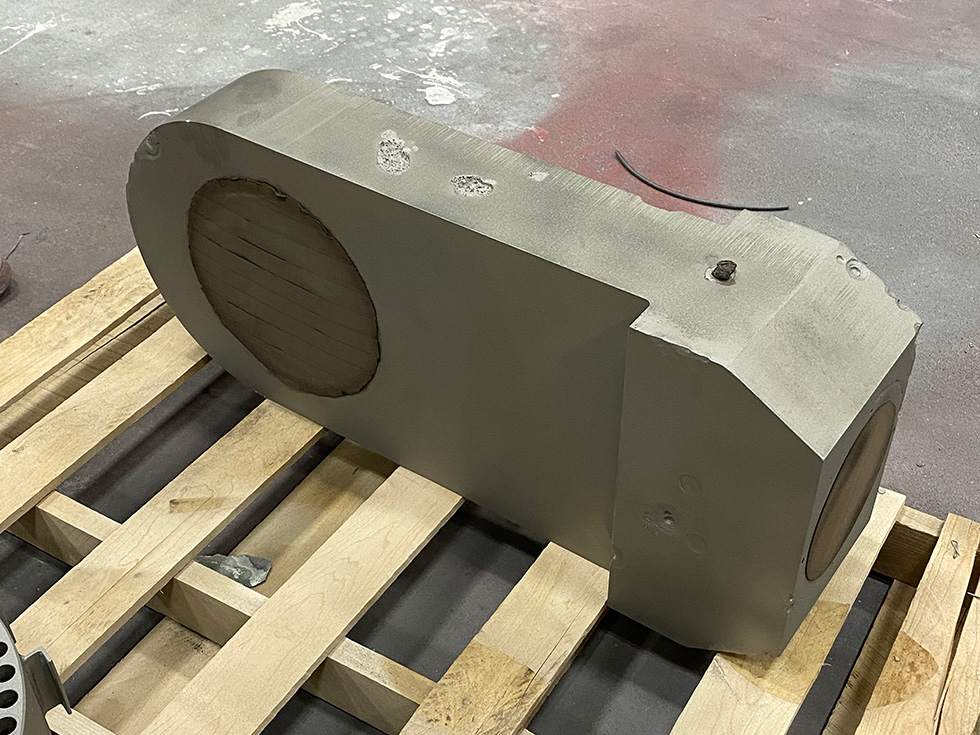

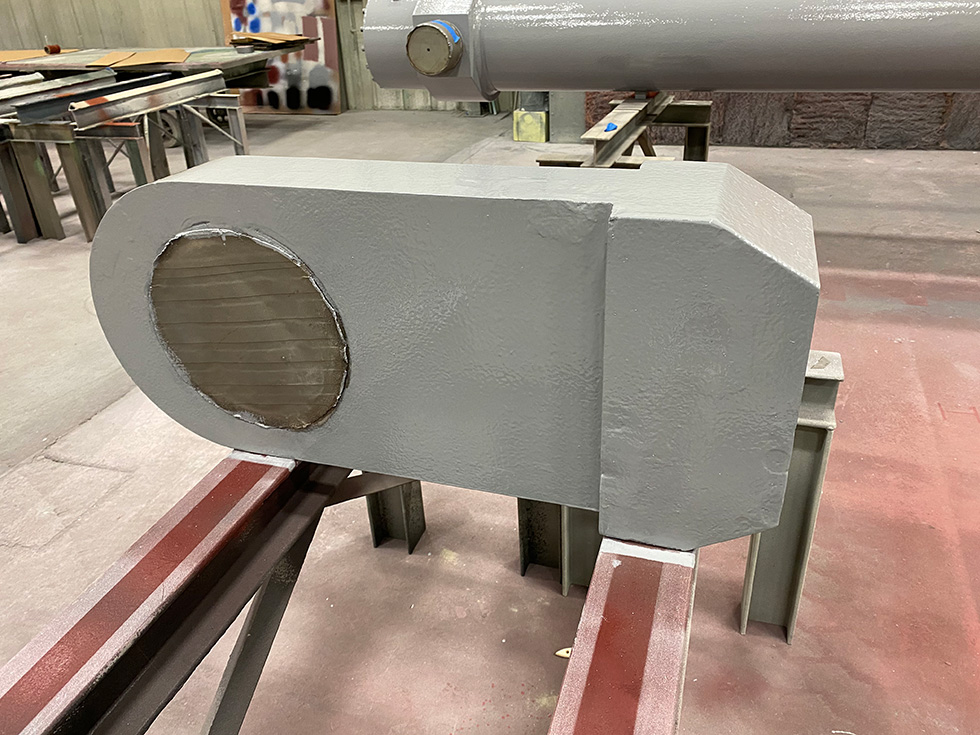

Any type of metal substrate that is cracked, pitted, or worn can be repaired with ENECON’s METALCLAD® CeramAlloy® CP+AC or METALCLAD® DurAlloy® after proper surface prep, to avoid welding and other techniques that might cause additional damage to the substrate or be labor intensive. After curing, the metal repair product can be grinded down to the desired shape and tolerance.

After the metal is repaired, the entire substrate can be coated with one of the following coatings to prevent the damage from occurring in the future. These coatings can also be applied to concrete substrates in indoor or outdoor applications.

- METALCLAD® CeramAlloy® CL+AC to resist corrosion and fluid-flow erosion

- METALCLAD® CeramAlloy® CBX to resist aggressive abrasion

- FLEXICLAD® DuraTough™ DL to resist cavitation

- CHEMCLAD® GP, SC, or XC for protection in harsh chemical environments

Common applications of this repair and coating process include:

- Internal pump and valve components

- Pipework

- Housings and tanks

- Heat exchangers

- Cyclones and separators

- Augers and chutes

- Primary and secondary containments